A CONTINUOUS LOW COST

BOTTLE & JAR COOLING

SYSTEM

Many food products, such as jams, drinks and sauces, are hot filled into glass containers directly

after cooking or pasteurisation. Unlike tin cans, hot glass cannot be directly placed into cold water

to cool for fear of breakage due to thermal shock. Forced cooling of such hot filled foods is,

however, generally recommended to reduce changes in product colour and flavour. Some products

are much more sensitive than others to changes of this type.

In many small-scale production units, hot containers are simply allowed to air cool and this may take

several hours. The situation is often made worse, in that in order to save space, the bottles are piled

into stacks and so cool even more slowly.

In larger manufacturing plants, hot, closed bottles are passed through continuous coolers in which

they meet zones of water sprays of gradually reducing temperature, thus overcoming the problem of

thermal shock. Such coolers are large, complex and expensive.

A simple, cheap system was developed

in the St Vincent Ministry of

Agriculture's Production Unit to allow

controlled cooling of both bottled fruit

drinks and jam jars, with production

rates being typically 50 to 150 packs

per hour.

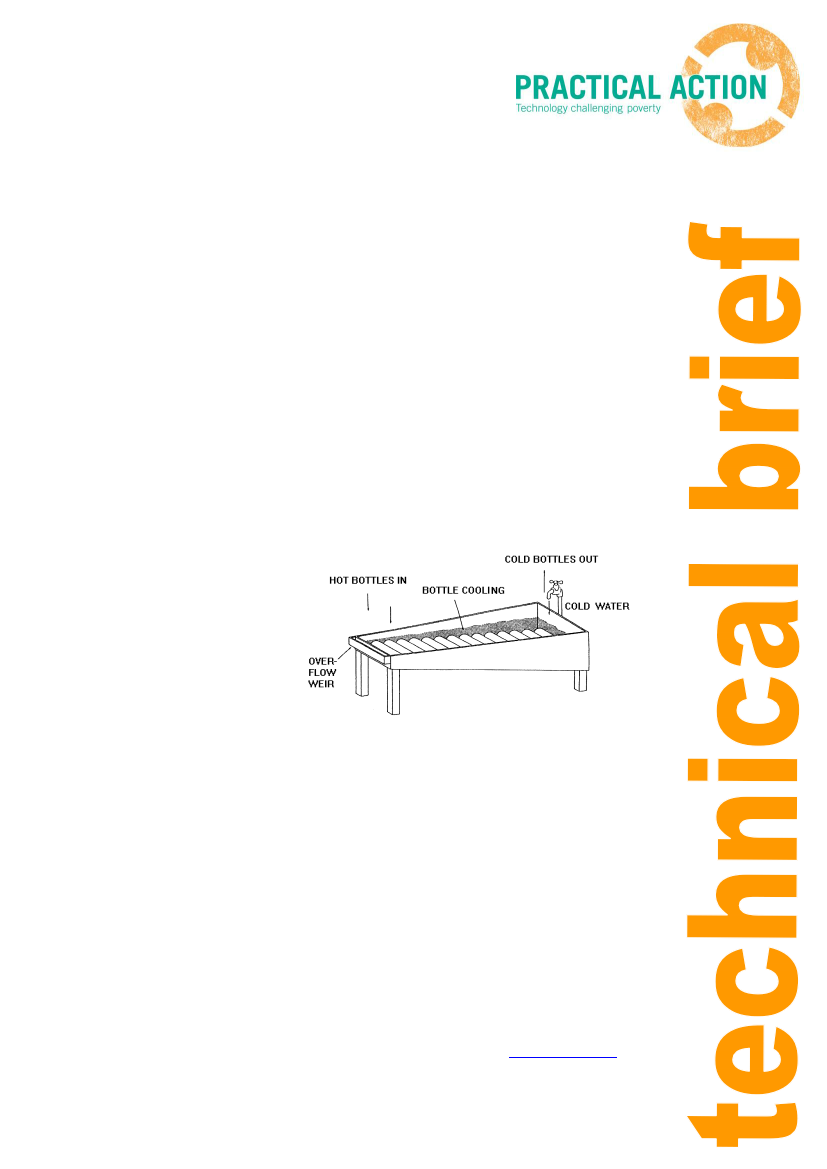

The basic system, see Figure 1,

consists of a long water tank set-up in

such a way that it automatically

develops zones of different

temperature along its length, or a

temperature gradient. The tank was

constructed from galvanised iron sheet

and was supported in an angle iron

cradle. The total length was 12ft and

the width, in order to accommodate

the largest bottle used was 13 inches.

Figure 1: Bottle cooling system

The base of the tank was sloped to

increase the depth of water from 0-8 inches along the length.

Mains water was fed continuously to the deep end of the tank, together with a controlled drip of

chlorine solution. The use of chlorinated water for bottle cooling is essential because when a hot

filled pack is first capped, the seal is never perfect. As the pack cools, the glass and the metal cap

seal firmly together and an internal vacuum forms. In effect, this means that in the early stages of

cooling the outside medium, whether it is water or air, can be sucked into the container by the

gradually forming vacuum.

Practical Action, The Schumacher Centre, Bourton on Dunsmore, Rugby, Warwickshire, CV23 9QZ, UK

T +44 (0)1926 634400 | F +44 (0)1926 634401 | E infoserv@practicalaction.org.uk | W www.practicalaction.org

___________________________________________________________________________________________________________

Practical Action is a registered charity and company limited by guarantee.

Company Reg. No. 871954, England | Reg. Charity No.247257 | VAT No. 880 9924 76 |

Patron HRH The Prince of Wales, KG, KT, GCB